Reduce Inventory Waste, Boost Profits - AI/ML-Enabled Demand Forecasting for Smarter Manufacturing

Mid-market manufacturing businesses often face various inventory challenges in managing supply chains. For example, companies usually struggle with accurate demand predictions because of evolving customer preferences and changing market trends.

What complicates this further is the need to streamline stock management and enhance prediction accuracy for sales and marketing campaigns. Also, there is constant pressure to implement innovative strategies to reduce waste.

Advanced manufacturing demand forecasting helps companies slash supply chain costs and significantly improve capacity planning, financial planning, and profit margins.

However, conventional forecasting methods and practices, often reliant on outdated data, gut instinct, and archaic Sales and Operations Planning processes, don’t keep up with dynamic market trends. This is where Artificial Intelligence (AI) and Machine Learning (ML) can save the day by improving forecasting efficiency and accuracy and determining incremental impacts of new initiatives.

A Gartner survey revealed that demand forecasting is the most popular ML application in supply chain planning. This study highlighted that about 45% of companies already use the technology.

Are you ready to incorporate ML/AI technologies into your demand forecasting toolbox?

Challenges with Traditional Demand Forecasting Methods

Demand forecasting is challenging because of the dynamic nature of customer behavior. Trends may shift overnight, influenced by several factors, such as the latest social media buzz, new product introductions by competitors and so forth. This makes it tricky to anticipate or predict future demand accurately.

While traditional stats methods certainly can provide a starting point, they don’t cut it in today's complex market environment.

Suppose a celebrity endorses a previously unknown fitness tracker that failed to make it big. A glowing endorsement from a popular fitness influencer is enough to boost the tracker's popularity. This surge in interest, driven by the celebrity's influence, could lead to a rapid increase in demand.

However, traditional forecasting methods may not anticipate it. The manufacturer may scramble to keep up with the unexpected wave of customers.

Incorporating Qualitative Data into Manufacturing Demand Forecasts

A common challenge in forecasting is that you have to integrate qualitative data into demand forecasts. For instance, customer sentiments and brand perception can heavily influence demand. The only problem is that they are tricky to quantify. For example, a negative product review that goes viral can cause demand to plummet.

This is a qualitative factor that traditional forecasting methods and techniques may not capture. Inaccurate forecasts often lead to inventory nightmares (overstocking because of poor reviews, understocking due to hype) and disrupted production. This can hinder manufacturing operations and affect the ability to capitalize on market shifts.

Fragmented Approach to Forecasting Manufacturing Demand

The digital revolution has created omnichannel businesses and retailers who juggle e-commerce, brick-and-mortar stores, and third-party distribution. This often creates unique forecasting challenges.

Managing a business enterprise at this scale usually promotes a ‘divide and conquer’ mentality, leaving departments and channels siloed.

Human Bias

Demand forecasts can be influenced by past experiences or intuition, leading to inaccuracies that can cloud judgment and make it harder to anticipate market shifts.

Introduction to ML/AI in Demand Forecasting

Many mid-market manufacturing firms now leverage ML/AI technologies for demand forecasting. Innovative companies and their private equity owners stand to gain immensely from this method. According to McKinsey, business organizations that use ML and AI-powered demand forecasting can reduce the errors they usually make in their supply chain networks by as much as 50%.

Also, AI and machine learning forecasting is much faster, more accurate and reliable, and more granular compared to other forecasting methods. You may wonder how it does this exactly.

Let’s say a company is using AI and ML. It can track every facet of its supply chain, from the number of products it is selling to when inventory will run out and when production needs to be ramped up. You can also keep tabs on which products aren’t selling as well as expected (leading to bloated warehousing and storage costs) and how demand and sales can fluctuate depending on the time of year.

With the democratization of powerful forecasting algorithms, ML and AI offer a powerful alternative to conventional methods of forecasting. Here's how:

Machine Learning

These algorithms easily analyze vast amounts of data, including:

Internal sales figures

External market trends

Social media sentiment

Call center logs

Competitive pricing data

Competitor reviews

They identify complicated patterns and relationships that most humans will miss.

Artificial Intelligence

AI is even better as it can use these patterns to learn and adapt to changing market dynamics. This means you get more nuanced and accurate forecasts.

Benefits of ML/AI for Demand Forecasting

AI-powered data analytics lets businesses meet and overcome the challenges associated with demand forecasting. According to McKinsey & Company, advanced analytics let retail businesses outperform their competitors by a whopping 68%.

Improved Forecast Accuracy

ML/AI algorithms can analyze a broader range of data points, leading to more precise forecasts that reflect real-world market conditions. Bike manufacturers may forecast a steady production rate based on seasonal trends and other historical data.

However, this approach is not effective as it neglects external factors. ML/AI can analyze weather forecasts predicting a mild winter, social media hype about indoor cycling, and online searches for specific models.

This improves forecast accuracy, potentially foreseeing higher-than-usual winter demand. As a result, the manufacturer adjusts production accordingly, avoiding stockouts and a line of disgruntled customers.

Cost Reduction and Efficiency Enhancement

Hedging your demand forecasts with safety stock can be expensive and lead to several issues. It undermines inventory KPIs and ties up inventory dollars, often leading to overstocks.

On the other hand, with a reliable forecast, logistics costs decline, and the number of open-to-buy grows.

This positively impacts manufacturing efficiency, improving inventory KPIs and overall profitability and liquidity. Accurate forecasts also minimize the need for emergency production runs.

Improved demand forecasting in manufacturing allows for better production planning, which streamlines your entire manufacturing process.

Reduced Markdowns

With more realistic and accurate demand forecasts, you aren’t forced to make drastic last-minute markdowns in order to sell off surplus stock. With AI-enabled forecasting, you can proactively plan price drops or set optimal discount prices to boost ROI.

Implementing ML/AI in Manufacturing

The most common goals or expectations businesses have from AI and ML are cost reduction, process automation, and process optimization. However, if you would like to use AI and ML capabilities in the manufacturing industry to the fullest extent, you must prepare for their integration.

So, how do you integrate ML/AI into demand forecasting to minimize waste and reduce cost?

Here's a roadmap to successful implementation:

Gather Pertinent Data

Gather pertinent data from credible sources, including historical sales figures, customer demographics, clickstream analytics and social media trends. Ensure the data is clean and organized for optimal analysis.

Addressing any data quality issues or integration challenges early will help prevent any hiccups later on.

Evaluate Demand Forecasting Tools

Several cloud-based and on-premise demand forecasting tools and platforms cater to different needs and budgets. The availability of best-in-class open-source tools has also skyrocketed over recent years. It is best to evaluate your specific requirements, keep your goals in mind, and select a solution that seamlessly integrates with your existing systems.

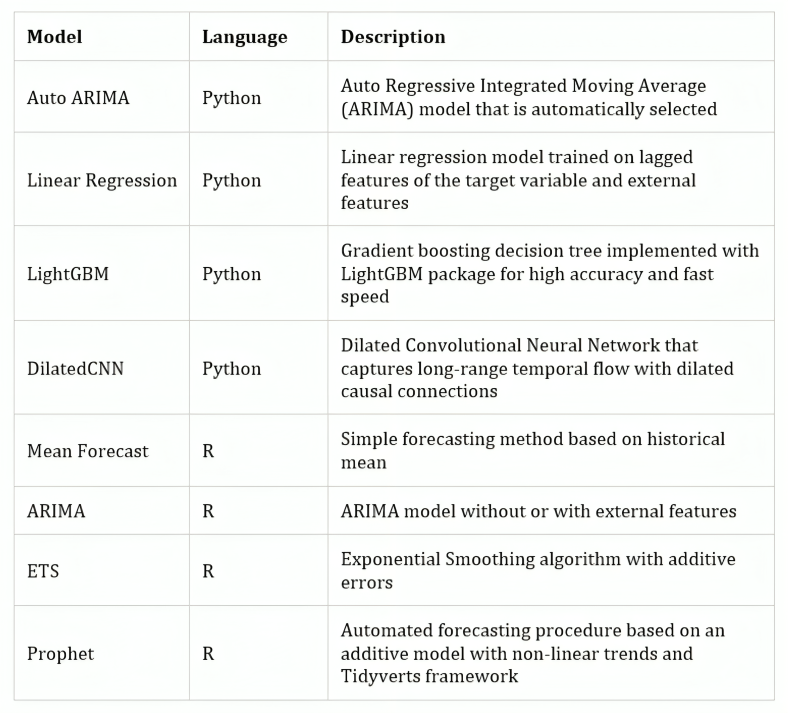

A list of key R/Python packages and algorithms available open source for ML-based forecasting. Courtesy of Microsoft Azure’s data science team.

Get feedback from stakeholders in different departments like IT and operations to ensure alignment and effective implementation.

Develop a Custom ML/AI Model

Work with specialized data scientists to develop a custom ML/AI model tailored to your manufacturing niche, data, and operating rhythm. Additionally, the right internal (or external) data experts can help you with historical sales data and organize structured data by product type, region, season, and relevant promotions that will be consumed by the forecast models.

Train the model on your historical data to fine-tune its forecasting capabilities. Data scientists may choose an appropriate ML algorithm, like Random Forest, Neural Networks, Gradient Boosting, or some combination of the above.

Continuous Model Monitoring and Adjustment

The developed model will not be a one-time solution and requires iteration. Continuously monitor its performance and adjust it as needed. Let’s say market conditions change and preferences evolve: yuour model will need tweaks, and you may have to retrain it with new data to keep its accuracy and relevancy intact.

Case Studies and Real-world Applications

The following case studies and real-world examples show how AI/ML can provide valuable insights and inform prudent decision-making.

The COVID-19 pandemic presented many unprecedented challenges for businesses. Many organizations, like UK manufacturer Marshalls, faced sudden stock shortages after previously holding excess inventory.

Marshalls integrated AI into their system to optimize inventory and navigate the unprecedented lockdown. This helped answer some critical questions:

Production levels

Minimum stock levels at various locations

Order fulfillment prioritization

The AI system made 4,000 data-driven forecasting decisions daily, helping Marshalls manage daily orders worth nearly £300,000.

However, there are other ML/AI success stories. P&G has created an AI-powered demand-sensing platform known as PredictIQ. This platform has helped P&G slash forecast errors by about 30% compared to conventional methods. PredictIQ analyzes real-time data from various sources, such as social media and POS systems, to detect demand signals and predict short-term fluctuations.

Future Trends and Developments

In the future, manufacturing demand forecasting will prioritize a more AI-powered, data-driven, and holistic approach. Companies are looking to leverage advanced analytics to produce responsive and accurate forecasts. Those who are not taking advantage of it will be left behind.

Emerging Technologies

Explainable AI (XAI)

Current ML/AI models are complex and can be like black boxes, making it challenging to understand how they arrive at their predictions. XAI is a powerful technique that answers important “why” and “how” questions about AI systems and XAI advancements will provide greater transparency in the reasoning behind forecasts.

An example of an XAI package available in Python called SHAP (SHapley Additive exPlanations). Courtesy of Moez Ali.

They can also address rising legal and ethical concerns. This allows manufacturers to build confidence and trust in the system's recommendations.

Edge Computing

Traditional AI models have limitations. They rely on centralized cloud computing for data processing. Edge computing is a network philosophy or distributed computing framework that enables IoT devices to reliably process data at the edge of the network.

It brings processing power closer to the data source (e.g., factory machines), enabling real-time analysis and faster decision-making based on up-to-the-minute data.

Future of Manufacturing Demand Forecasting - Key Predictions

Here are some ML/AI trends and predictions that should be top of mind:

Forecasts will be produced and updated continuously thanks to advancements in data processing and edge computing. As a result, manufacturers can make near-instantaneous adjustments to production plans based on real-time market changes or fluctuations in customer behavior.

Demand forecasts will become increasingly granular. They will account for customer segments and individual customer preferences and buying habits.

Conclusion

Traditional forecasting methods rely on historical data and struggle to keep pace with dynamic markets. ML/AI accounts for many variables and offers a powerful solution for more accurate and efficient demand forecasting.

Demand forecasting for the manufacturing sector will be data-driven and AI-powered. If you use ML/AI for demand forecasting, you will be better positioned to boost efficiency, slash costs, and improve customer satisfaction. Simply put, these capabilities are table-stakes in 2024.

Want to make the most of ML/AI for your manufacturing operations and minimize costs and waste? Contact Revology Analytics today to learn how we can help you implement a customized demand forecasting solution.

Subscribe to

Revology Analytics Insider

Revenue Growth Analytics thought leadership by Revology?

Use the form below to subscribe to our newsletter.